Color Steel Sandwich Panel

Polystyrene (EPS) sandwich panel

Characteristics:

Lightweight

Low water absorption

Good warm proof and heat transfer resistance

Could be used in low temperature environment

Width of panels: 930mm/1000mm

Specification:

Galvanized steel sheet thickness: 0.35 to 0.6mm

Total thickness: 50 to 150mm

Lengths of panels: customized

Resistances of heat-transfer process: 0.03 to 0.04W/m.k

Density: 8 to 12kg/m3

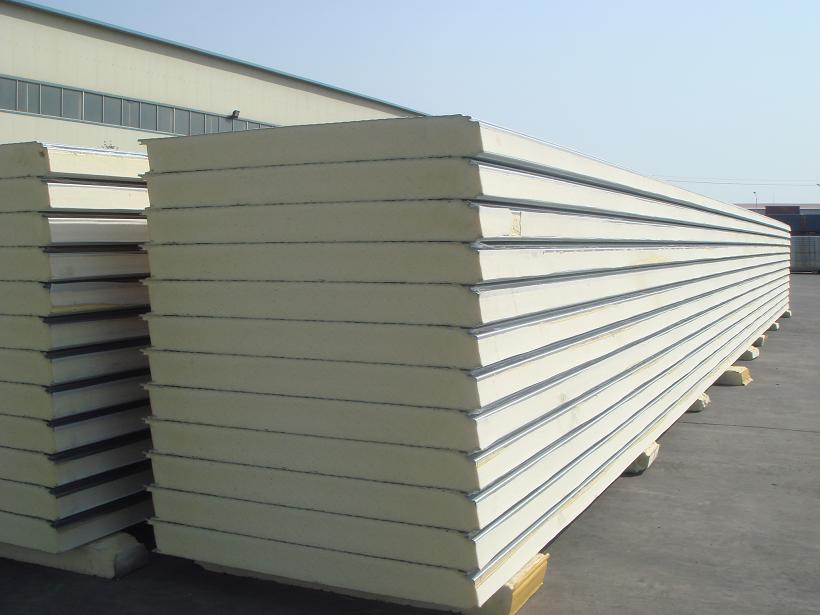

Polyurethane (PU) sandwich panel

Widely used in ship-craft, vehicle, and building and refrigeration room

Air conditioned warm keeping, decoration and other fields.

Characteristics:

Lightweight

High strength

High bearing capacity

Easy and quick installation

Low water-absorbing capacity

Good bend and compression resistance

Specification:

Width of panels: 930mm/1,000mm

Galvanized steel sheet thickness: 0.45 to 0.6mm

Total thickness: 50 to 150mm

Lengths of panels: customized

Specific gravities: ≥40kg/㎡

Resistances of heat-transfer process: ≤0.023W/m.k

Sound deadening: 21.5db

Limits of fire resistance: ≥220Kpa

Density: 40 to 120kg/m3

Water absorption for 24 hours: ≤5%

Rock wool sandwich panel

It is made of color steel sheet and rock wool warm proof, could be widely used in scavenged project (pharmaceutical/biologic/electronic), ship-craft, food-stuff, air-condition, factory, boiler room, floors, activity room, factory, refrigeration house, facility room, office-separation, indoor noise-absorption and so on.

Characteristics:

1. Fire-proof

2. Good warm proof and heat transfer resistance

3. Good bend and compression resistance

4. High bearing capacity

5. Flexibility in fixing

Specification:

1. Galvanized steel sheet thickness: 0.4 to 0.6mm

2. Total thickness: 50 to 150mm

3. Width of panels: 930mm

4. Lengths of panels: customized

5. Specific gravities: 10.2 to 17.7kg/㎡

6. Resistances of heat-transfer process: ≤0.044W/m.k